Markets

MÜNZING’s additives and waxes are formulated to enhance the properties of our customer's products. The applications range from printing inks to all kinds of coatings, including wood, architectural and industrial coatings. Our additives are also used in industrial fluids, with their versatile fields of application, such as metalworking fluids, coolants and industrial cleaners. The building and construction industry, as well as the paper and water treatment industry also benefit from our products. The acquisitions of FENTAK® and MAGRABAR® have also enabled us to create an attractive portfolio for wood and food processing applications.

Adhesives & Heatseal

MÜNZING's outstanding range of raw materials enables our customers to get the most out of the adhesives and sealants they manufacture, whether these are water-based, solvent-based, hot melt adhesives, or adhesives based on natural polymers. We offer additives for pressure-sensitive adhesives, packaging adhesives, construction adhesives, industrial adhesives, industrial sealants, and heat seal applications. Adhesives can be formulated based on a variety of different chemistries, either natural or synthetic based. Our portfolio for adhesives includes "Defoamers for process deaeration and application defoaming", "Wetting Agents for better wetting on difficult substrates", "Rheology Modifiers to optimize the flow profile for your application", "Dispersants for dispersing and stabilizing of solids" and "Wax Dispersions to improve heat sealing and barrier properties". We also offer bio-based additives to improve the ecological footprint.

More About this MarketAntifreeze, Engine Coolants and De-Icing

It is essential in all types of engines that coolant or antifreeze is used to control the running temperature of the equipment. Failure to protect the fluid from freezing can significantly damage the cooling core of an engine. The main attribute of these systems is the wide operating temperature of -40°C to +110°C. A typical coolant operating environment is +0°C to +90°C, reaching optimal temperature within a few minutes. Any foam control agent must be stable in these conditions for many years. Compatibility and persistency of the formulants is essential in these environments. The formulations contain strong electrolytes, glycols, and ethers. The defoamer under such conditions should remain compatible with the coolant, that is a traditional glycol fluid, organic acid-based, or a hybrid fluid. The MÜNZING siloxane or polyalkylene glycol chemistries are designed to remain active and compatible in the different coolant systems. The FOAM BAN® defoamers remain persistent throughout the lifetime of the fluid. De-icers for aircraft applications require further environmental regard since these are used in the open environment.

More About this MarketArchitectural Coatings

Architectural coatings, like paints, plasters, and other coatings, are found on the exteriors and interiors of our buildings. MÜNZING additives portfolio for architectural coatings is extensive and includes defoamers, dispersants, rheology modifiers, leveling- and wetting agents, as well as micronized waxes, wax dispersions and emulsions. These products are provided for a variety of architectural coatings applications, such as exterior decorative paints and plasters for facades, interior wall paints, and from clearcoats up to highly filled systems. Our products serve easy application of architectural coatings in brush, roller, or spray application and prolong their durability and hydrophobicity. To meet the increasing demand for renewable, environmentally friendly paints, we offer additives for the formulation of water-based low-VOC or free architectural paints. Another important aspect is the increased use of more bio-based elements in the additive groups to ensure the shift towards a more sustainable coatings industry.

More About this MarketBuilding & Construction Products

MÜNZING has extensive experience in developing and producing powder additives for the construction industry. Our product range includes powder defoamers, powder wetting agents, and shrinkage reducing additives for a broad spectrum of applications, including self-leveling compounds, joint fillers, tile adhesives, mortars, and plasters. Powder defoamers, for example, are used in dry-mix mortars for none or low air void-containing products to achieve maximum density, mechanical strength, and little capillary transport effects. This, for instance, is essential in repair mortars, self-leveling compounds, anchoring mortars, and tile grouts. Shrinkage-reducing agents (SRA) are water-miscible or soluble substances that are reducing the surface tension of the water phase and which are reducing the evaporation rate of water during the setting and curing of a mortar system. Powder wetting agents are used to improve the wetting of hydrophobic components like synthetic fibers and carbon blacks and for reducing water demand plus de-agglomeration of inorganic pigments and fillers.

More About this MarketCan Coatings

The MÜNZING product range for can coatings offers the best-suited solutions for these high-end coatings, which have a decorative as well as a protective function. They must fulfill numerous requirements such as chemical resistance, sterilization, excellent adhesion on ferrous and non-ferrous metal, outstanding flexibility as well as improvement of the corrosion protection of the metal. At the same time, can coatings are applied inside the metal container to protect the content of the can and to ensure a long product life cycle. These kinds of coatings must fulfill very high standards. After all, they are in direct contact with our food. Our micronized waxes and wax dispersions provide excellent slip and abrasion resistance to external can coatings to enable high production speed.

More About this MarketEnergy & Oil Field

Energy extraction now demands higher extraction efficiency and less waste production in the separation of gases and fluids. Environmental awareness is leading to the development of greener defoamer chemistries that have minimal impact upon the environment but still perform as expected in providing high efficiency and persistency during the extraction process. The industrial area covers scrubbing, dehydration, separation, deliquefaction, and drilling in the gas, oil, and coal industries. The extraction of oil and gas requires the separation/purification of the hydrocarbon from water as an emulsion. The emulsion is extremely foamy, so to provide optimal running efficiency in the separator or dehydration units, the AGITAN® or FOAM BAN® products can be used in an environmentally responsible manner. The AGITAN® OF-52 has the highest accreditation for the North Sea (CEFAS R-rating) for gas deliquefaction and separation. In land-based oil and gas operations, the FOAM BAN® 4950 or MS-550 may be used.

More About this MarketEngineered Wood

Engineered wood consists of a number of types of construction materials which are made from wood. These materials are put together in such a way that they give high strength and structural integrity to their desired applications. The types of products would include Plywood, Laminated Veneered Lumber (LVL) and Cross Laminated Timber (CLT). In order to maximise performance in use of the end product or of the production process manufacturing the materials, MÜNZING has a range of FENTAK® additives which can help achieve the needs of the customer. Processing additives such as release agents to stop the sticking of panels to press plates when pressing and product enhancers like edge seals for increasing moisture resistance would be typical of the types of thing we can offer.

More About this MarketFood Processing

The MAGRABAR® food defoamers are amongst the most strictly regulated defoamers in the marketplace for food additive and food processing. The defoamers provide maximum foam control, little to no odor or taste, and are ready to be added to any liquid or powder recipe. Our food defoamers are available in two main types: food additive or processing aid. The food additive defoamer is used to give a technical effect in the food that the consumer directly consumes. For example, a defoamer is used to control foam in a powder drink formulation. The processing aid is a defoamer that is used to manufacture the food item; any defoamer remaining in the consumable product is purely incidental, like a defoamer used to manufacture a sauce or carbonated beverage. The MAGRABAR® products are Kosher and Halal certified, suitable for vegetarian and vegan diets, and gluten-free. Furthermore, all products are palm oil-free and formulated with cropped vegetable oils, which makes them biobased to a large extent. The portfolio is completed by several organic certified products that can be used as food additives as well as processing aids.

More About this MarketHI&I Cleaners and Surface Care

MÜNZING products are mainly used in two areas of the cleaner industry: home and industrial businesses, covering large-scale commercial operations. These are typically the fabric cleaning and machine floor operations for the hotel, health and hospitality businesses. The second aspect is the care market where waxes such the carnauba and polyethylene waxes are used for high gloss applications for furniture. Besides furniture care, the care market also includes floor, leather and fabric care, as well as window cleaners. The industry is now focusing upon lowering the environmental impact of these formulations with ecologically sound principles of biobased ingredients or biodegradable molecules. An example of our continual research and development into these areas are the bio-based high-performance and low foaming surfactants METOLAT® R series products and the bio-based waxes to replace the micro-plastic opacifiers found in fabric detergents and softeners. In applications such as detergents, where good formulation compatibility and excellent foam control are required, the FOAM BAN® 3D siloxane products are recommended. In terms of industrial cleaning of metal parts using high-pressure machine washing equipment, such as those used to clean engine casings or machine metal parts to remove oily or waxy residues, FOAM BAN® HP series products need to be considered for their superior defoaming and compatibility properties under such severe conditions.

More About this MarketIndustrial Coatings

The application areas for industrial coatings are diverse, including protective coatings for metal, plastic, general industrial, and powder coatings. With its wide range of additives for industrial coatings, MÜNZING offers a suitable solution for every customer application. This product portfolio includes defoamers, dispersants, rheology modifiers, leveling and wetting agents, as well as micronized waxes, wax dispersions and emulsions. The trend towards smart coatings can also be seen in the field of industrial coatings. Our additives and waxes help to achieve properties such as corrosion resistance, self-cleaning, easy-to-clean, improved durability, or various barrier properties.

More About this MarketIndustrial Overlays

Industrial films/overlays are normally based on phenol formaldehyde (PF) resins, melamine formaldehyde (MF) resins or a combination of both. One of the main applications of industrial films/overlays is the production of a surface coating for plywood used, for example, in concrete forming applications. These films/overlays range from papers with a basis weight of 40-80 g/m², known as phenolic surface films (PSF) and high density overlays (HDO), to films/overlays with a basis weight of >100 g/m², known as medium density overlays (MDO). Other uses of industrial films/overlays are closely related to PSF, HDO and MDO films/overlays and include applications such as durable truck decking, non-slip industrial flooring and moisture barriers. MÜNZING offers a variety of FENTAK® additives for the manufacturing process of industrial films/overlays, such as wetting or release agents, colorants, defoamers and plasticizers.

More About this MarketLaminates

Laminates come in a huge variety of colors styles and finishes. They are applied to many things in our everyday life from Kitchen Surfaces where food is prepared to the flooring we walk on. Typically constructed of a resin impregnated paper adhered onto a wood panel substrate, the concept is simple but yet so complex when it comes to the variety of different finishes, effects and performance demanded by todays consumer. Born out of an idea by employees of a laminates producer, FENTAK® additives were established over 30 years ago and have grown ever since. Under the ownership of MÜNZING the products are a great fit to the other existing ranges and continue to become more and more diversified. Whether it is a basic resin catalyst, wetting agent or release agent that is needed or something as complex as an anti-abrasion additive or high performance plasticiser then we certainly have a solution and can assist with our highly skilled technical expertise in helping you improve your laminating process or products in a number of ways.

More About this MarketLeather Finishing

Modern leather products are offered in a wide variety of colors, glosses, and haptic. They receive many of these properties through coating or treatment with a leather finishing. These product solutions can cover defects, add gloss or matting effects to the leather or e.g. give it a unique vintage look. MÜNZING wax additives help to achieve such effects, add water repellency, abrasion resistance and are used to adjust the degree of gloss or soft touch.

More About this MarketMasterbatch

Masterbatches are additives used for coloring plastics or for the introduction of other functional additives. They are used in all typical processes of the plastics industry, like injection molding, blow molding, and extrusion. They usually consist of a carrier-polymer, wax as a dispersing agent and pigments. By helping the pigments to disperse very finely, MÜNZING’s high-performance wax dispersing agents increase color strength by up to 5%–15%, reduce pigment consumption and therefore save cost. The very fine particles of our micronized CERETAN® waxes also improve multiple processing aspects like e.g. lowering of the filter pressure, reduction of clogging of filters and enabling a more rapid mixing.

More About this MarketMetalworking Fluids and Lubricants

The increasing technical demands of high-performance CNC machining with technical metals in complex forms provide the perfect opportunity to use MÜNZINGs FOAM BAN® high-performance defoamers. Applications range from aircraft parts machining to metal stamping and forging fluids. The metalworking fluids are oils that are classified into three main groups – soluble oils, semi-synthetic with high and low oil content, and fully synthetic oil systems. All systems provide their own unique attributes to foam control, compatibility, and wetting performance. Some problems are observed in the dilution of the fluid to produce the working emulsion. Depending on local water quality, foaming may be an issue with soft water dilutions. Formulation stability may be affected by hard water conditions. Both problems are caused by low or high levels of calcium and magnesium salts within the natural water. The FOAM BAN® 3D siloxane-containing defoamers are specially designed with emulsifiers that promote good compatibility in a broad range of water hardness environments. Defoamers that are especially strong at controlling foam are FOAM BAN® HP 900 products. The fore-mentioned defoamers are practically formulated into all systems that require fast knockdown, persistent foam control, and low treat rates. In cases where silica is not permitted, such as some aerospace applications, then wax-based FOAM BAN® products will provide a way to combat foam over a prolonged period of time.

More About this MarketNon-aqueous Lubricants

Non-aqueous lubricants are typically known as engine lubricants and drive train lubricants where an engine requires lubrication to maintain optimal efficiency and longevity; or in a gearbox application as in motorcycles, wind turbines, or a gearbox system in a metal foundry. All lubricant applications have demanding specifications. However, all applications require the defoamer to deaerate the fluid while impacting foam stabilization as little as possible. Lubrication only occurs between two surfaces when a fluid is present between those surfaces. Any entrained air will interfere with this lubricating property. Degradation of metal parts, premature wear, and overheating could lead to catastrophic equipment failure. The market is rapidly moving towards low viscosity and foamier synthetic lubricants to reduce frictional losses and to run extended refill service intervals. In doing so extreme defoamer filter performance and persistency is demanded. This benefits the FOAM BAN® 3D siloxane chemistries with their ability to pass through low micron pore size filters. In applications where silica-free or low silica is demanded, then a polymeric FOAM BAN® or a hybrid (polymer/siloxane) is recommended. In the food industry, where NSF HX-1 standards are needed in any areas where food contact may be required for any given fluid, we are able to offer specific FOAM BAN® types.

More About this MarketPaper

MÜNZING has been developing and producing auxiliaries and additives for the production and coating of paper and board for many decades. The partnership with the paper industry goes back to the early days of our company when the Heilbronn paper mills were supplied with sulfuric acid. The portfolio includes defoamers and deaerators for both wet-end and paper coating and starch applications. Other product groups include pigment and filler dispersion, substrate wetting and auxiliaries for dewatering acceleration and broke treatment, as well as rheology additives for viscosity control of paper coatings. Our application technology and highly qualified field service ensure a high level of service for the applications we support during trials and in the ongoing operation. Extensive measuring and metering equipment is available for this purpose.

More About this MarketPrinting Inks

Printing inks are part of our daily life. They are used for means of information or decorative purpose in print media, catalogs, and brochures, on packaging, textiles and articles of daily use. The major application processes are flexographic, gravure, offset and screen printing. MÜNZING has extensive expertise in specialty additives for printing inks and offers a broad portfolio of additives to the printing ink manufacturers, inclusive of defoamers, dispersants, rheology modifiers, emulsifiers, wetting and leveling agents, micronized and coated waxes as well as wax dispersions and emulsions. Depending on the application, printing inks have to meet many different requirements, where our additives are of great value. They help to reduce anti-blocking and rub out and improve slip, gloss, matting, and scratch resistance.

More About this MarketSurface Finishing

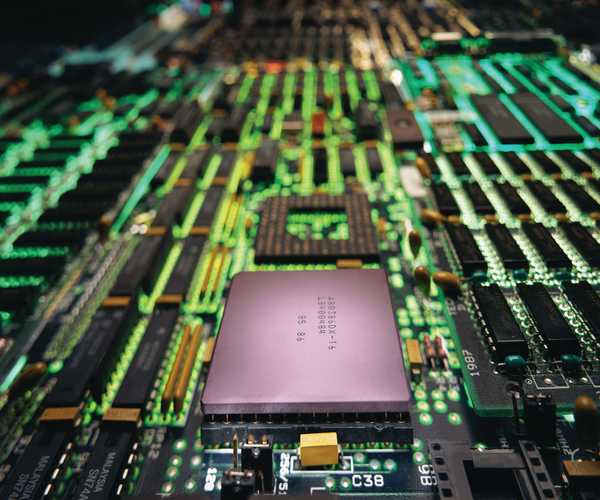

Surface finishing applications are primarily focused upon MÜNZINGs FOAM BAN® 3D siloxane chemistry to the industry that provides safe, clean, and reliable cleaning materials for the PCB (printed circuit board) and silicon wafer industry. This market is defined by the PCB strippers, cleaners, plating compounds and polishing slurries for the wafer finishing. One of the most important aspects of this industry is to control the volume of foam present in the fluid. Air entrainment in the cleaning solutions will prevent effective cleaning of surface impurities. For wafer polishing, air bubbles trapped between the grinding faces will lead to surfaces scratching which results in high waste rates and risks damaging the finishing tool. Our defoamer range has been specifically designed with high defoaming efficiency and easy rinse properties. The 3D siloxane chemistry reliably and easily rinses from surfaces so as not to affect further surface treatments. Our products are essential in the area of promoting foam control and excellent formulation compatibility.

More About this MarketTankside Defoamers

Efficiency, compatibility, and persistency are the three main attributes a MÜNZING defoamer provides to successfully formulate a fluid that maintains the required tribology and cooling for modern high-performance fluids. The tank side applications are sensitive to the slower, less energetic method of defoamer incorporation into the header tank or sump. When a machine operator notes higher levels of foam being produced in the machining unit, it is important for the operator to manually dose defoamer, like FOAM BAN® 3D siloxane chemistry. The machine may automatically stop if the foam level sensor is activated, which causes losing machine time, possible cutting tool damage, and reduction of production output. Tank side applications are intended to support the fully formulated metalworking fluid over prolonged periods. The defoamer formulated in the metalworking fluid may not have long-term concentrate stability or long-term persistency once the fluid is operating in the high shear conditions in the machining unit. Small additions of tank side defoamer will prolong the lifetime of the diluted metalworking fluid, reduce the running cost of the machine, and also reduce fluid waste or recycling costs.

More About this MarketWater Treatment & Process Water

MÜNZING offers a comprehensive product portfolio for solving all possible foam problems in the field of municipal and industrial wastewater treatment plants. In addition to foam control in clarifiers and digesters, this also includes foam removal during sludge dewatering at the decanter and vacuum evaporator. Other important applications include process water treatment in MDF board and cement fiberboard production. The focus in these applications, in addition to excellent effectiveness at high process temperatures, is on the high biodegradability and environmental compatibility of the raw materials used. Our technicians will support you with product selection and on-site application support.

More About this MarketWood Coatings

Wood is the world’s most important natural material for building and construction. Wood provides high versatility and stability in combination with excellent workability, but it is sensitive to external influences like abrasion, humidity, temperature variations, germs, etc. MÜNZING has long-lasting expertise in wood coatings and our aim is to help wood coating formulators around the world with our additives and our technical service to develop products that provide their customers with the best possible solution. Our broad product range of defoamers, dispersants, rheology modifiers, emulsifiers, wetting and leveling agents, micronized and coated waxes as well as wax dispersions and emulsions, provide great features to all kinds of wood coating, like improvement of anti-blocking, scratch resistance and slip, as well as modification of haptic effects.

More About this MarketWood Panels

Available in a number of forms for a number of applications, wood panels are certainly versatile in the tasks they can perform. Widely used in many construction applications such as framework for house building as well as substrates for the more decorative requirements of highly modern furniture designs, the raw panel types consisting of Particleboard, Medium Density Fibreboard (MDF) and Oriented Strand Board (OSB) are usually behind a large volume of all of these applications. Where a flat, smooth, large, straight surface or structure is needed a wood panel is usually the solution. MÜNZING has extensive knowhow in the production of these products and can recommend a number of solutions from our FENTAK® range of additives to improve both the end quality of the product and also the processes in which they are produced.

More About this Market